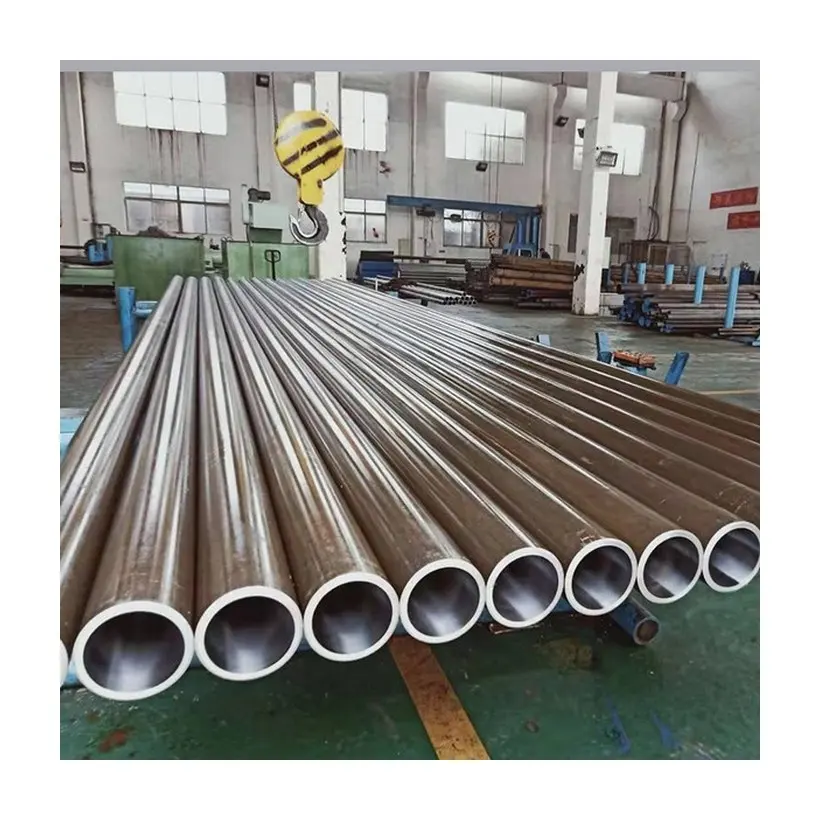

34CrMo4 Gas Cylinder Tube: High-Strength Alloy for Demanding Applications

Introduction:

34CrMo4 stands as a formidable alloy structural steel renowned for its exceptional endurance and creep strength at elevated temperatures. Primarily employed in cylinder manufacturing and structural components operating under substantial loads, this steel variant offers outstanding performance in various demanding applications. From vehicle transmission parts to turbine-generator rotors, spindle components, and heavy-load drive shafts, 34CrMo4 plays a pivotal role. Additionally, its utility extends to locomotive traction gears, supercharger transmission gears, connecting rods, and spring clamps that bear significant loads. The steel finds purpose in even more specialized contexts, such as oil drilling pipe joints and fishing tools for depths up to 2000 meters.

Properties and Applications:

The distinctive characteristics of 34CrMo4 alloy steel make it an ideal choice for a range of demanding applications. The alloy exhibits remarkable strength and resilience at high temperatures, rendering it suitable for applications where extreme conditions prevail. Its exceptional creep resistance ensures reliable performance even under prolonged stress.

In the automotive sector, 34CrMo4 finds utilization in transmission components and engine parts that experience high loads. The steel’s durability and robustness contribute to the efficient functioning of vehicles under diverse conditions. Moreover, in the realm of power generation, particularly in turbine-generator rotors and spindles, 34CrMo4′s enduring properties are critical for maintaining safe and efficient operation.

Challenges and Solutions:

While 34CrMo4 offers exceptional attributes, its weldability poses a challenge. The steel’s poor weldability necessitates meticulous pre-welding preparation, including preheating, followed by post-welding heat treatment and stress relief. This careful approach ensures the integrity of welded joints and maintains the overall performance of components.

Heat Treatment Strategies:

To harness the full potential of 34CrMo4, heat treatment procedures are pivotal. The steel is commonly subjected to quenching and tempering processes, enhancing its mechanical properties and ensuring optimal performance in demanding applications. Additionally, high and medium-frequency surface quenching can be employed to further enhance its surface hardness. Subsequent tempering at low and medium temperatures imparts the desired balance of strength and toughness, rendering the steel suitable for its intended applications.

In the realm of high-strength alloy steels, 34CrMo4 stands as a stalwart performer. Its exceptional endurance, creep strength at high temperatures, and versatile applications make it a cornerstone of industries requiring robust and reliable materials. By addressing its weldability challenges through careful preparation and employing appropriate heat treatment strategies, the steel’s potential can be fully harnessed. Whether in the automotive sector, power generation, or specialized applications, 34CrMo4 remains an invaluable asset for constructing components that endure extreme conditions and heavy loads.