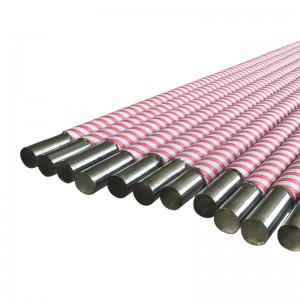

1. Superior Hard Chrome Plating: The piston rod is meticulously coated with a high-quality hard chrome plating, which provides excellent resistance to corrosion, wear, and abrasion. This ensures a long lifespan for the rod, even in demanding operating conditions.

2. Enhanced Strength and Durability: The piston rod is manufactured using premium-grade materials, such as high-strength steel, which imparts exceptional strength and durability. This robust construction enables the rod to withstand heavy loads and high-pressure applications with ease.

3. Precise Dimensional Accuracy: The piston rod is precisely machined to meet strict dimensional tolerances. This accuracy guarantees a perfect fit within the hydraulic cylinder, promoting smooth and efficient operation. It also minimizes the risk of leakage or seal damage.

4. Reduced Friction and Seal Wear: The hard chrome plating on the piston rod provides a smooth and low-friction surface, minimizing frictional losses and seal wear. This feature enhances the overall efficiency of the hydraulic system, resulting in improved energy savings and reduced maintenance costs.

5. Versatile Application: The hard chrome plated piston rod is suitable for a wide range of hydraulic applications, including industrial machinery, construction equipment, agricultural machinery, and more. Its versatility makes it a reliable choice for various industries, ensuring optimal performance in diverse hydraulic systems.