Features:

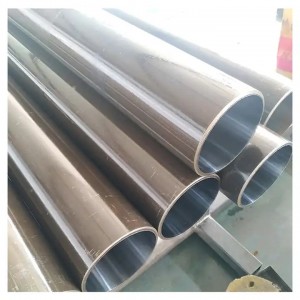

- Smooth Internal Surface: Honed ID Tubing is characterized by an exceptionally smooth and consistent inner surface. The honing process removes any surface imperfections, creating a mirror-like finish that reduces friction and improves fluid flow.

- Dimensional Accuracy: The honing process ensures tight dimensional tolerances within the tubing’s inner diameter. This precision is critical for achieving a proper fit with components like pistons, seals, and bearings.

- Improved Sealing: The smooth surface of honed tubing enhances the effectiveness of sealing elements, such as O-rings and seals, preventing fluid leakage and maintaining consistent pressure levels.

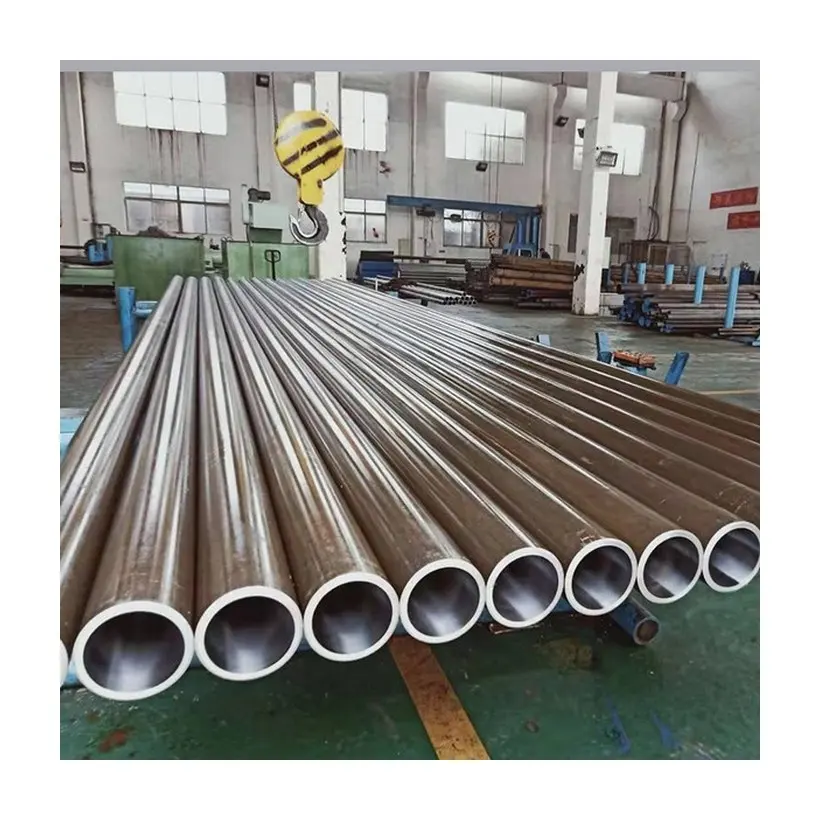

- Material Quality: Honed ID Tubing is typically made from high-quality steel or other materials known for their strength and durability. The material choice ensures the tubing can withstand pressure, load, and environmental conditions.

- Applications: This type of tubing finds applications in hydraulic cylinders, pneumatic systems, precision machinery, and other situations where controlled fluid movement or precise linear motion is required.

- Corrosion Resistance: Depending on the material used, honed tubing can exhibit corrosion-resistant properties, extending its operational lifespan and maintaining its performance integrity.

- Surface Finish Options: Manufacturers may offer various surface finish options for honed tubing, catering to specific applications and requirements. Different finish grades can impact factors such as friction and wear resistance.

- Customization: Honed ID Tubing can be customized to meet specific needs, including variations in dimensions, material composition, surface treatments, and lengths.

- Quality Assurance: Manufacturers employ quality control measures to ensure the tubing’s inner surface finish and dimensions conform to industry standards, guaranteeing reliable performance.

- Ease of Integration: Honed ID Tubing is designed for easy integration into hydraulic or pneumatic systems. It can be paired with other components to create efficient and reliable fluid power solutions.

Write your message here and send it to us